Search This Supplers Products:Magnetic materials, magnetic equipment and devicesAuto Partstelecom devicesElectronicselectricalsmetals

What is high temperature SmCo magnet ?

High

temperature SmCo

magnets that can withstand temperatures of 500°C and

550 °C

Many

key devices in the aerospace and other fields, such as aircraft motors and

generators, microwave function tubes, magnetic bearings and inertial navigation

devices, require high-performance high-temperature permanent magnet

materials.

Among

the existing permanent magnet materials, the strongest NdFeB magnet has the highest room temperature performance, but its

Curie temperature is 312 °C, and

the maximum working temperature is usually not more than 250 °C;

the

Curie temperature of AlNiCo magnet is 850 °C ,

The maximum operating temperature can reach 520 °C, but

the coercive force of the magnet is very low (< 145 kA / m), so it can not manufacture small and light components; SmCo magnet has a high Curie temperature (750 ~ 920 °C),

Moreover,

it has strong magnetocrystalline

anisotropy and high coercivity at room temperature (> 1990 kA / m), which is

the first choice for high temperature permanent magnet material.

The

main reason why the traditional 2:17 SmCo magnet is not suitable for high temperature applications is

that its coercive force decays rapidly with increasing temperature (coercive

force temperature coefficient β ≈-0.30% / °C). By

adjusting the alloy composition and heat treatment process of the traditional

2:17 type SmCo magnet , the microstructure and microcomposition

inside the material are controlled to reduce the temperature coefficient of the

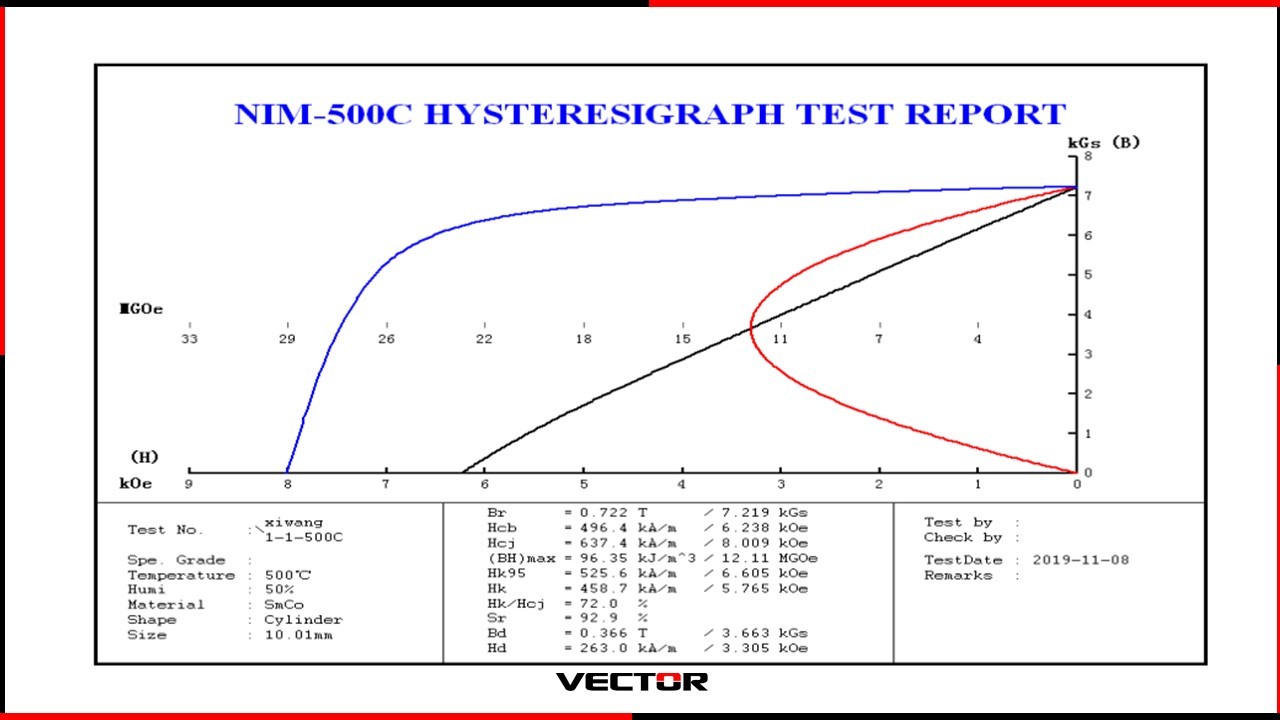

coercive force of the material and increase the use temperature. In the end, we successfully made a 2:17 type SmCo high temperature magnet that can be applied at 500 ° C and 550 ° C.