Search This Supplers Products:Magnetic materials, magnetic equipment and devicesAuto Partstelecom devicesElectronicselectricalsmetals

FASCIA GUN

publisherEvan

time2020/10/26

- Fascia gun, full name muscle fascia relaxation massage gun, used for high-frequency shock therapy for fascia relaxation.

What is a fascia gun?

Fascia gun, also called deep myofascial impact instrument, is a soft tissue rehabilitation tool that relaxes the soft tissues of the body through high-frequency impact. Fascia gun can be understood as a civilian version of DMS (Electric Deep Muscle Stimulator), the vibration frequency will change during use, and its basic function is similar to DMS.

Fascia is attached to bones and gathered in joints. It is a tissue that connects joints and muscles. Tendons are tough and rigid, restraining and protecting the joint muscles and other sports tissues. Generally, after strenuous exercise, the muscles feel tight, which is actually the fascia doing small movements.

After a fitness exercise, the muscles will feel tight, and the joints of the muscles will be tighter. It is like the muscles are fastened in one place. When the muscles want to stretch, there is not only a pain, but also a sense of restraint. The function of the fascia gun is to shake the tight muscle fascia apart so that there is no sense of restraint after the fitness exercise, and the muscle extension will be more comfortable.

How does the fascia gun work?

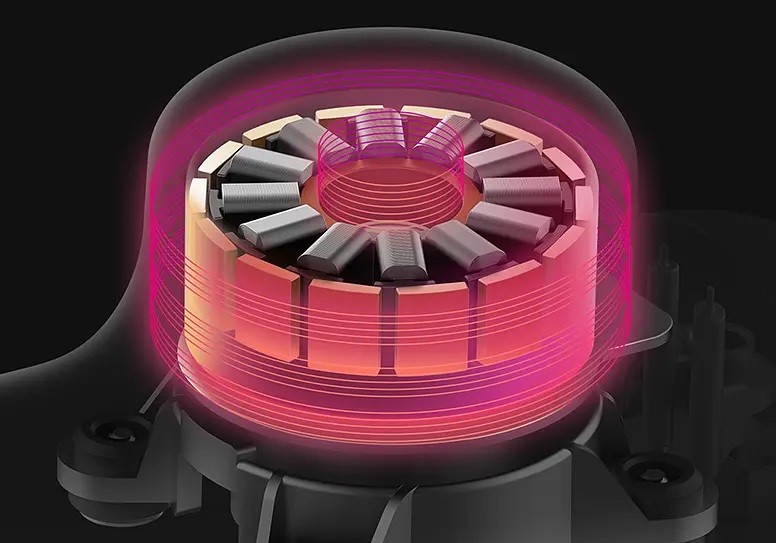

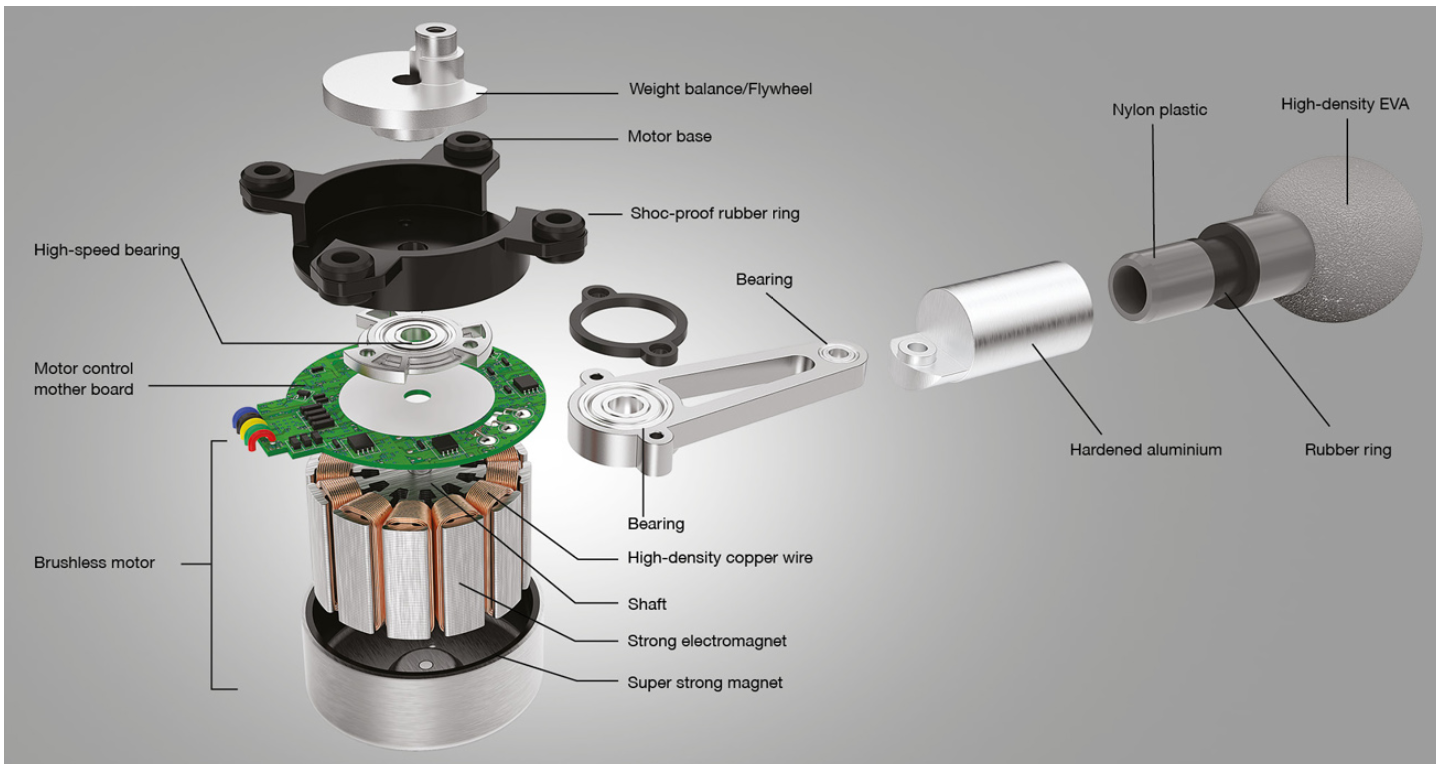

The fascia gun uses a special high-speed brushless motor to drive the reciprocating motion, generating high-frequency vibration, which acts on the deep layer of the muscles to reduce local tissue tension, relieve pain, and promote blood circulation.

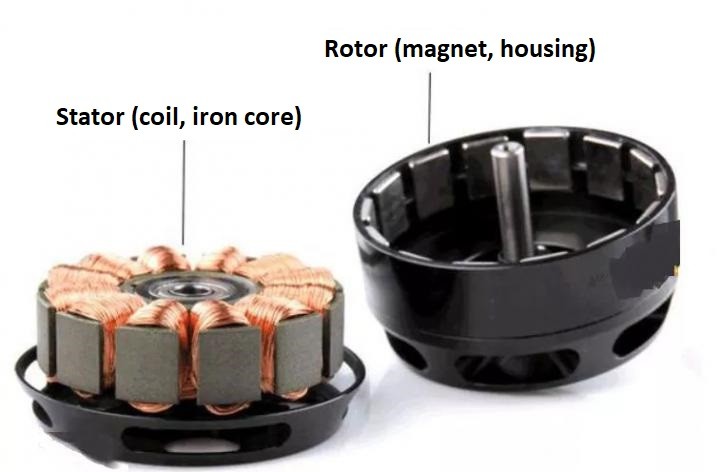

The core component of the fascia gun is a brushless DC motor, which is composed of a motor body and a driver. It is an atypical mechatronic product. Because the brushless DC motor runs in a self-control mode, it will not add a start winding to the rotor like an asynchronous motor that is started under heavy load under variable frequency speed regulation, and it will not oscillate and lose a step when the load changes suddenly. The permanent magnets of medium and small capacity brushless DC motors are now mostly made of rare earth neodymium iron boron (Nd-Fe-B)materials with high magnetic energy product.

Brushless DC motors use semiconductor switching devices to realize electronic commutation, that is, electronic switching devices are used to replace traditional contact commutators and brushes. It has the advantages of high reliability, no reversing sparks, and low mechanical noise. It is widely used in high-end audio jacks, video recorders, electronic instruments and automated office equipment. The brushless DC motor consists of a permanent magnet rotor, a multi-pole winding stator, and a position sensor. The position sensor commutation of the stator winding current in a certain order according to the change of the rotor position (that is, detecting the position of the rotor pole relative to the stator winding, and generating a position sensing signal at a determined position, which is processed by the signal conversion circuit To control the power switch circuit, switch the winding current according to a certain logical relationship). The working voltage of the stator winding is provided by the electronic switch circuit controlled by the position sensor output.