Search This Supplers Products:Magnetic materials, magnetic equipment and devicesAuto Partstelecom devicesElectronicselectricalsmetals

Why NdFeB is chosen for wireless charging magnetic connector?

publisherEvan

time2020/11/20

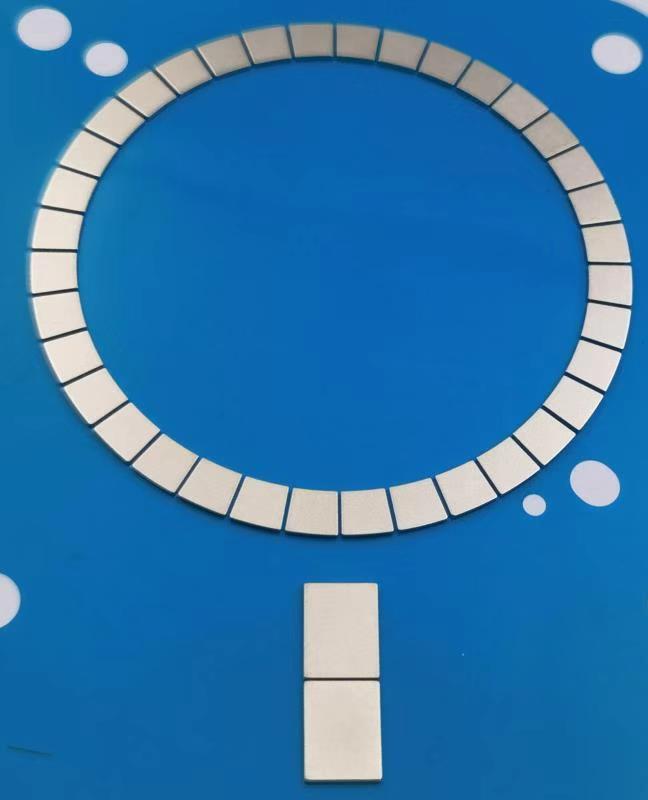

- The maturity of wireless charging technology has brought the vigorous development of this field, and the design of various usage scenarios is also very extensive. For example, the design of using magnets to absorb the wireless charging transmitter and electronic device receiver is particularly attractive to consumers. Put it lightly and it will automatically locate and adsorb, and then start charging, such as Apple's newly released wireless charging Magsafe, wireless charging treasure, etc..

Why NdFeB is chosen for wireless charging magnetic connector?

The maturity of wireless charging technology has brought the vigorous development of this field, and the design of various usage scenarios is also very extensive. For example, the design of using magnets to absorb the wireless charging transmitter and electronic device receiver is particularly attractive to consumers. Put it lightly and it will automatically locate and adsorb, and then start charging, such as Apple's newly released wireless charging Magsafe, wireless charging treasure, etc.. There are many types of magnetic materials. Why did the wireless charging magnetic connector design chooses NdFeB Magnets? Why not low-cost ferrite and AlNiCo, nor SmCo, which has good temperature resistance and strong pull force. This article will talk about characteristics of these materials, and analyze why wireless charging chooses NdFeB as the connector.

Why isn’t the SmCo magnet selected for wireless charging? SmCo magnets are very close to NdFeB in terms of performance and are the best choice to replace NDFEB in many fields. SmCo magnets are also resistant to high temperature and corrosion. Usually, the capability of magnets will decrease in performance as the temperature rises, that is, the pull force power will decrease.Electronic products such as mobile phones usually heat up when charging, and SmCo has good heat resistance. But why doesn’t SmCo eventually become a magnet for wireless charging magnetic connectors either? First of all, in terms of the temperature characteristics. The working temperature of SMCO materials range from 250°C to 350°C. Its temperature resistance is second to none among all magnets, but today our stage is a magnetic connector for wireless charging.

In daily life, it’s noticeable that an electric device will heat up when charging. Although it’s hot when touched by hands, the temperature will not exceed 100°C anyway. Furthermore, with the advancement of technology, the heat generated by electronic devices during the charging process is limited within 45°C. Therefore, the excellent temperature characteristics of SmCo magnets is a surplus in wireless charging magnetic connectors. Similarly, the corrosion resistance of SmCo materials is not very useful here. Magnets are assembled or molded into mobile phones or charging heads, so the working environment of the magnets is relatively dry and clean.This will not affect the magnet. Moreover, the electroplating process can largely avoid such risks. Additionally, there are two more important reasons why SmCo is not selected as the magnetic connector of wireless charging. First,the cost of the material is high; second, the SmCo material is of great hardness but relatively brittle, and it is easy to break when bumped.

According to incomplete statistics, the global downstream demand for high-performance NdFeB magnets is projected to be about 74,300 tons in 2020. The unique characteristics of NDEFB make it one of the most widely used magnetic materials. First of all, NdFeB is titled the “king of magnetism,”for the maximum N57 energy product of VECTOR MAGNETS can reach 454kJ/m³, which is almost ten times that of ferrite and almost two times that of SmCo, meaning that NdFeB can use a smaller volume design yet provide greater pull force power,which guarantees the portability of wireless charging equipment. Depending on the coercivity, the working temperature of NdFeB can range from 80°C to 250°C,perfectly meeting the requirements of any charging environment. Therefore, the magnetic force will not be weakened due to the temperature rise during the charging process, and the pull forceforce will not decrease. Although the main raw material of NdFeB is rare earth PrNd, the prices of which fluctuate in the market, it still cost less than SmCo. Moreover, in terms of the mechanical properties, the hardness (HV) of NdFeB is between 500 and 600 with strong machinability. It can be processed into the required shape through various processes such as grinding, cutting, peeling, milling, and drilling.

The three main features of NdFeB are strong magnetic properties, easy processing,and moderate material cost, making NDFEB the best choice for wireless charging magnetic connector magnets.