Search This Supplers Products:Magnetic materials, magnetic equipment and devicesAuto Partstelecom devicesElectronicselectricalsmetals

Are graphene batteries hype or is it really futuristic tech?

publisherGordon

time2021/01/21

- Graphene is considered a revolutionary energy storage material due to its strong electrical conductivity. In the field of EV, the concept of "graphene battery" has been repeatedly mentioned, which seems to have become a breakthrough in current electric vehicle battery technology. The graphene technology battery is called a "milestone black technology", but with this pursuit, the controversy has never stopped. Is the "graphene battery" a hype? Or will it really change the world?

What’s Graphene?

Graphene is a hexagonal flat film composed of carbon atoms in a

honeycomb structure. It is only one carbon atom thick, so it is a material with

a two-dimensional structure. It was "teared" by physicists Andre Gaim

and Konstantin Novoselov of the University of Manchester in 2004 by "tearing" graphite with tape.

The mechanical exfoliation method uses the friction and relative

movement between an object and graphene to obtain a thin layer of graphene

material. This method is simple to operate, and the obtained graphene usually

maintains a complete crystal structure.

Graphene has excellent electrical and thermal conductivity, so

it is currently the material with the smallest resistivity in the world.

Graphene is also the thinnest, strongest, and strongest new type

of nanomaterial found so far. Graphene is called "black gold" and is

the "king of new materials". Scientists even predict that graphene

will be "completely" Changing the 21st century". It is very

likely to set off a disruptive new technology and new industrial revolution

sweeping the world.

In this battery, graphene is not used as the positive or

negative electrode material of the battery, but only to help the lithium-ion

battery last. Of course, objectively speaking, the performance of this battery

is already very impressive, but it is comparable to real graphene. The battery

is a far cry.

In fact, before that, news about "graphene-super

battery" like this kind of gimmicky research results is not uncommon.

"Graphene battery" does not

exist?

Graphene has three applications in the battery field: one is

directly used as a positive/negative electrode material; the other is as a

conductive additive, which is added to the positive/negative electrode

material, or the electrode material is composite modified to improve Electrode

conductivity and charge-discharge rate; third, as a current collector or

current collector coating, used to improve battery power characteristics.

The application of graphene in lithium-ion batteries mainly

adopts the latter two methods. Because graphene is directly used as a negative

electrode material, its surface characteristics are easily affected by the

outside world, the stability is extremely poor, and there are problems such as

low efficiency at the first time, and it is difficult to meet the performance

requirements of lithium-ion batteries.

Graphene materials mixed with traditional battery materials can

significantly improve battery charge and discharge, cycle life, etc. It has

also become a winning point for power battery companies in the new round of

market competition.

Looking at the graphene industry across the country, adding graphene as a basic material to various existing battery materials has become a common practice among mainstream battery companies in China.

Why is the hype of graphene batteries more than practical?

It is not difficult to find that it is difficult to find a detailed introduction to graphene batteries on many encyclopedias and professional battery portals. Lack of many necessary technical parameters, such as energy density, voltage, cycle life, etc. As for batteries, how can people believe the overwhelming news of a battery without a clearly defined basic structure? The more news, will it be evidence that the "graphene battery" is unreliable?

So why is the graphene battery like a caged beast? At present, there are many internal and external problems that need to be solved urgently when using graphene batteries as materials:

1. The cost is unacceptable. Traditional conductive carbon black and graphite are sold per ton, while graphene is sold per gram. I don’t know that the price of carbon black and graphite can be reduced to a price similar to that of electrical carbon black and graphite, even according to some media reports. Yuan/gram, converted into a ton, would cost 3 million yuan/ton. Taking a step back, even if a "super battery" can be made, its price is unacceptable for us "poor" people.

2. The process is not compatible. The excessive surface area of graphene will cause a lot of process problems in the processes of dispersing and homogenizing the existing lithium-ion batteries. If the battery factory adjustment process will be a huge project, and there is no sufficient profit margin driven by the breakthrough progress of performance indicators at this time, and the surface characteristics of graphene are greatly affected by the chemical state, batch stability, cycle life, etc. There are a lot of problems, and so far, it can’t meet a bunch of problems encountered in production.

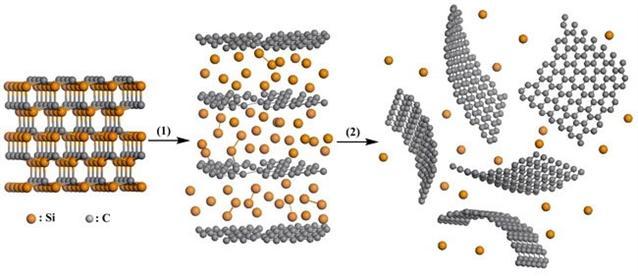

3. If graphene is used as a negative electrode (replacement of graphite with a theoretical capacity of 360mAh/g): theoretically up to twice the capacity of graphite negative electrode (720mAh/g), the efficiency is too low, and the performance is greatly affected by the surface state. In contrast, silicon, its theoretical capacity is nearly 10 times that of graphite, and there have been many scientific research and industrial grade achievements in suppressing powdering and cracking in recent years.

Therefore, the "graphene battery" is originally a lithium-ion/lead-acid battery doped with graphene, and there is no replacement problem, because this technology is simply "you can only watch from a distance and not play with it"!

The road to mass production is long and difficult

Graphene materials have a long way to go from laboratory to engineering application, and then to commercialization. It is more necessary to do the first batch of demonstration applications of graphene and its modified materials in industrial products.

From the current point of view, graphene batteries have more or at least disadvantages in terms of congenital, technical, and external factors.

At least for the time being, the application of graphene batteries in actual scenarios requires a lot of A long way to go.