Search This Supplers Products:Magnetic materials, magnetic equipment and devicesAuto Partstelecom devicesElectronicselectricalsmetals

Magnetic Particle Testing

time2021/04/30

- Magnetic Particle Testing

Magnetic Particle Testing

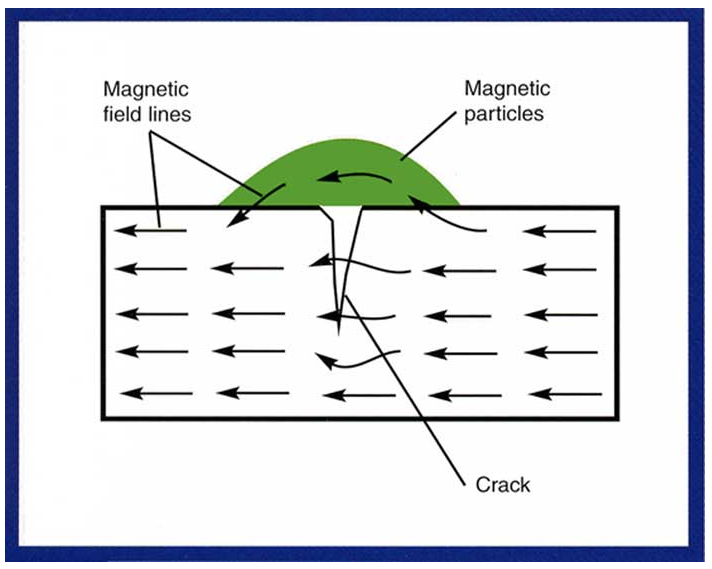

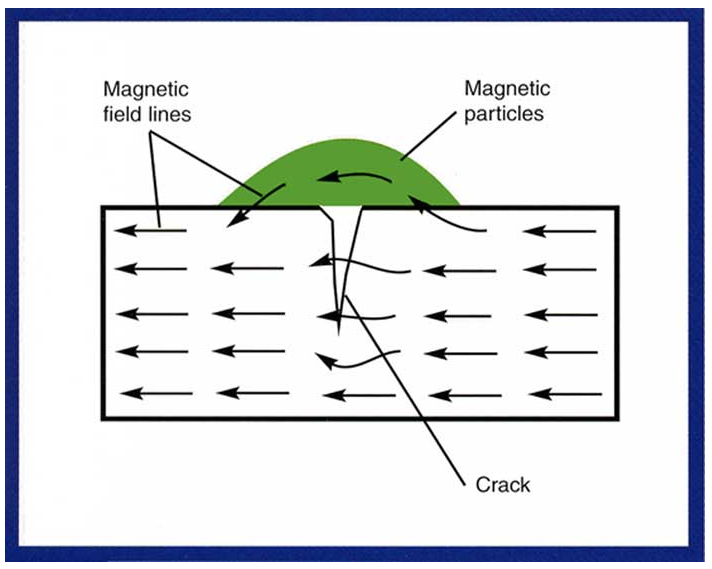

Magnetic particle inspection is also known as MT or MPT, which is suitable for inspection methods near the surface of magnetic materials such as steel.Use the principle that iron is attracted by magnets for inspection.During the magnetic particle inspection, the object to be tested receives the action of magnetic force, and the magnetic powder (magnetic micro powder) is scattered on its surface.Then, the leaking magnetic force leaking out of the defective part of the surface will attract the magnetic powder to form an indication pattern. The indicator pattern is dozens of times larger than the actual defect, so it is easy to find the defect.

Magnetic particles are applied to the surface of the specimen. The specimen is then magnetised. If flaws are present the magnetic particles form an

arrangement around the fault. This method is used on magnetic materials such as steels and cast irons. Magnetic particles can detect defects up to 18 mm below the surface of a weld.

Magnetic particle inspection method

1,Pre-treatment

If grease, paint, rust, or other foreign matter adheres to the flaw detection surface, it will not only prevent the magnetic powder from being adsorbed on the scar, but also cause the magnetic powder to adsorb to the part other than the scar to form a suspicious image.

Therefore, before magnetization, a physical or chemical treatment is used to remove dirt and foreign matter.

2,Magnetization

It is very important to magnetize the test object properly.

Usually, a magnetization method perpendicular to the direction of the scar and the direction of the magnetic force line is used.In addition, for proper magnetization, various methods can be used according to the shape of the object to be detected.

3,Use of magnetic powder

In order for the magnetic powder to be adsorbed between the magnetic poles of the scar to form a detected image, the magnetic powder used must be easily magnetized by the weak magnetic field of the scar and adsorb to the magnetic poles, that is, a certain adsorption performance is required.

In addition, it is required that the magnetic powder image formed must have a high degree of recognition.Generally, the magnetic powder used in magnetic particle inspection includes white, black, red and other different magnetic powders used under visible light, and fluorescent magnetic powders that use fluorescent light.In addition, depending on where the magnetic powder is used, there are powdery dry magnetic powder and wet magnetic powder dispersed in water or oil.

4,Observation

To observe the magnetic particle image attached to the scar, it is necessary to create an easy-to-observe environment.

Ordinary magnetic powder needs to be observed in the brightest possible environment, while fluorescent magnetic powder needs to use ultraviolet light to make the surroundings as dark as possible to be easy to observe.