Search This Supplers Products:Magnetic materials, magnetic equipment and devicesAuto Partstelecom devicesElectronicselectricalsmetals

Do you know what is heavy rare earth NdFeB magnet pure metal non-contact direct infiltration method and heavy rare earth NdFeB permanent alloy contact direct infiltration method?

time2022/09/30

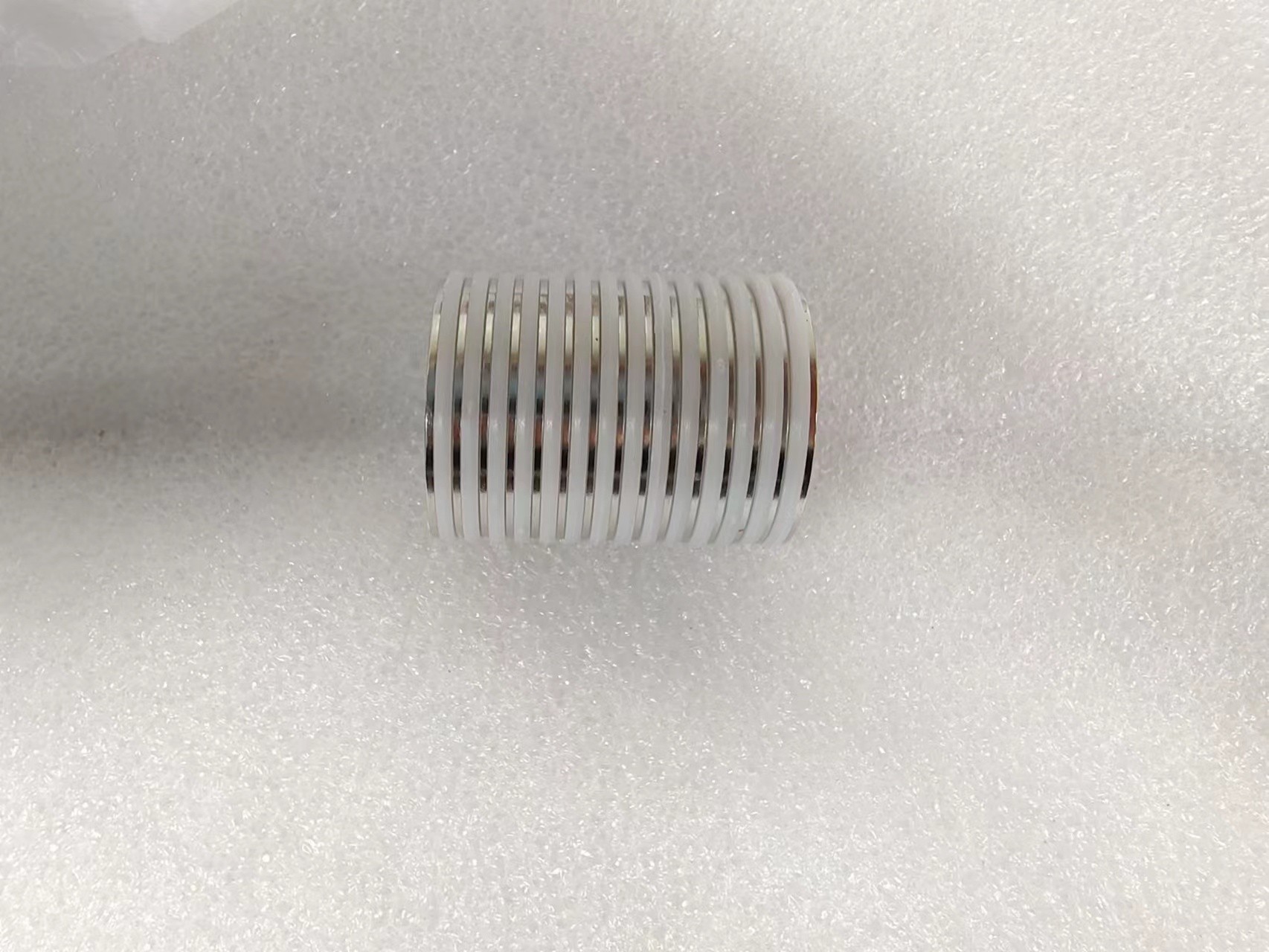

- Pure metal non-contact direct infiltration method for heavy rare earth NdFeB magnets

In fact, using the principle of vapor pressure and vacuum evaporation technology, pure metal is directly infiltrated into rare earth NdFeB magnets.

In fact, using the principle of vapor pressure and vacuum evaporation technology, pure metal is directly infiltrated into rare earth NdFeB magnets. The evaporation method avoids the difficulty of coating and can increase the thickness of rare earth NdFeB magnets to 7mm, but it brings the following problems:

①The equipment investment is large, and the equipment with a daily output of 300 kg is 6-10 million;

②The evaporated heavy rare earth particles not only accumulate on the surface of the magnet, but also accumulate a lot on the inner wall of the evaporation equipment, which will gradually cause serious contamination to the equipment. The worse it is, the vacuum cannot be achieved even after several years of use; that is why the heavy rare earth utilization rate of the evaporation method is only 80%, and the cost is high.

③ The evaporated heavy rare earth particles can only be upwards (it is a bit like smoked chicken in the image), in order to achieve uniform infiltration on all surfaces of the rare earth NdFeB magnet, the requirements for the placement of the workpiece are very high. If the workpiece is placed If the method is inappropriate, there will be areas that have not penetrated; the contact part between the workpiece and the pallet is blocked by the grid, so the film cannot be formed in this area, which affects the uniformity of the final diffusion layer, and the product still has the hidden danger of poor consistency