Search This Supplers Products:Magnetic materials, magnetic equipment and devicesAuto Partstelecom devicesElectronicselectricalsmetals

About Casting Stress

time2024/04/30

- Casting stress in AlNiCo magnet production can be divided into thermal stress and shrinkage stress. To minimize stress, simplify designs, ensure symmetry and uniform wall thickness. Employ simultaneous solidification techniques for equilibrium and prevention of thermal stress. Aging treatments like natural and thermal aging help eliminate stress. By combining these measures, high-quality AlNiCo magnets with minimal casting stress and superior performance can be achieved.

About Casting Stress

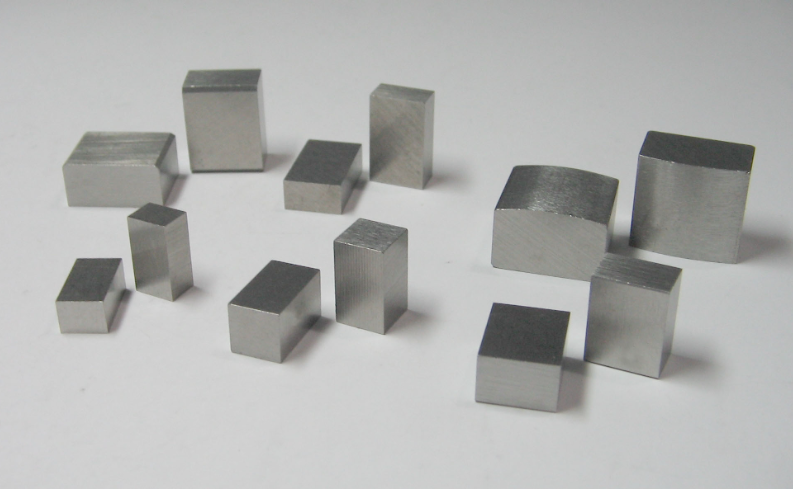

When it comes to producing aluminum-nickel-cobalt magnets, we often encounter issues related to product stress. Let's take a closer look at what Casting Stress actually is.

Casting stress can be mainly divided into two types: thermal stress and shrinkage stress.

Thermal Stress

Thermal stress refers to the stress caused by uneven shrinkage during the solidification and cooling process of the casting. Thicker sections with slower cooling experience tension, while thinner sections or surfaces with faster cooling experience compression. The greater the difference in wall thickness or the higher the alloy's linear shrinkage rate or elastic modulus, the greater the thermal stress. In directional solidification, the uneven cooling speed of different parts of the casting leads to significant thermal stress, making the casting prone to deformation and cracks.

Shrinkage Stress

Shrinkage stress occurs during the solid-state shrinkage of the casting, caused by external forces such as the mold, cores, and gating system. Generally, when the casting cools down to an elastic state, restricted shrinkage generates shrinkage stress, which typically manifests as tensile stress. Once the cause of the stress is eliminated (e.g., removal of sand or gating system), the shrinkage stress dissipates. Therefore, shrinkage stress is a temporary stress. However, if the casting experiences a combination of shrinkage stress and thermal stress that exceeds its tensile strength at the moment before sand removal, cracks may occur.

let's dive deeper and explore the measures we can take to minimize and eliminate casting stress.

(1) Design Matters: Simplify, Symmetrize, and Equalize.

When it comes to casting, complexity can lead to increased stress. By designing castings with simpler shapes, symmetry, and uniform wall thickness, we can reduce the variation in cooling temperatures and ultimately minimize casting stress.

(2) Simultaneous Solidification.

Simultaneous solidification is the key to maintaining equilibrium. By employing techniques that minimize temperature differences across different parts of the casting, we can achieve near-simultaneous solidification. This helps prevent the formation of thermal stress and cracks, resulting in minimal casting deformations.

(3) Aging Treatment.

Aging treatment is a powerful ally in our battle against casting stress. It includes natural aging, thermal aging, and resonance aging. Natural aging involves exposing the casting to an open-air environment for six months or more, allowing internal stress to dissipate naturally. Thermal aging, also known as stress relief annealing, entails heating the casting to a specific temperature, holding it there, cooling it down, and then removing it at room temperature. This process further enhances stress elimination.

Remember, the pursuit of high-quality castings AlNiCo requires a holistic approach. By combining these measures, we can achieve optimal results and deliver AlNiCo magnets with minimal casting stress and exceptional performance.